Customer Services

🔮 Elevate Your Metalworking Game!

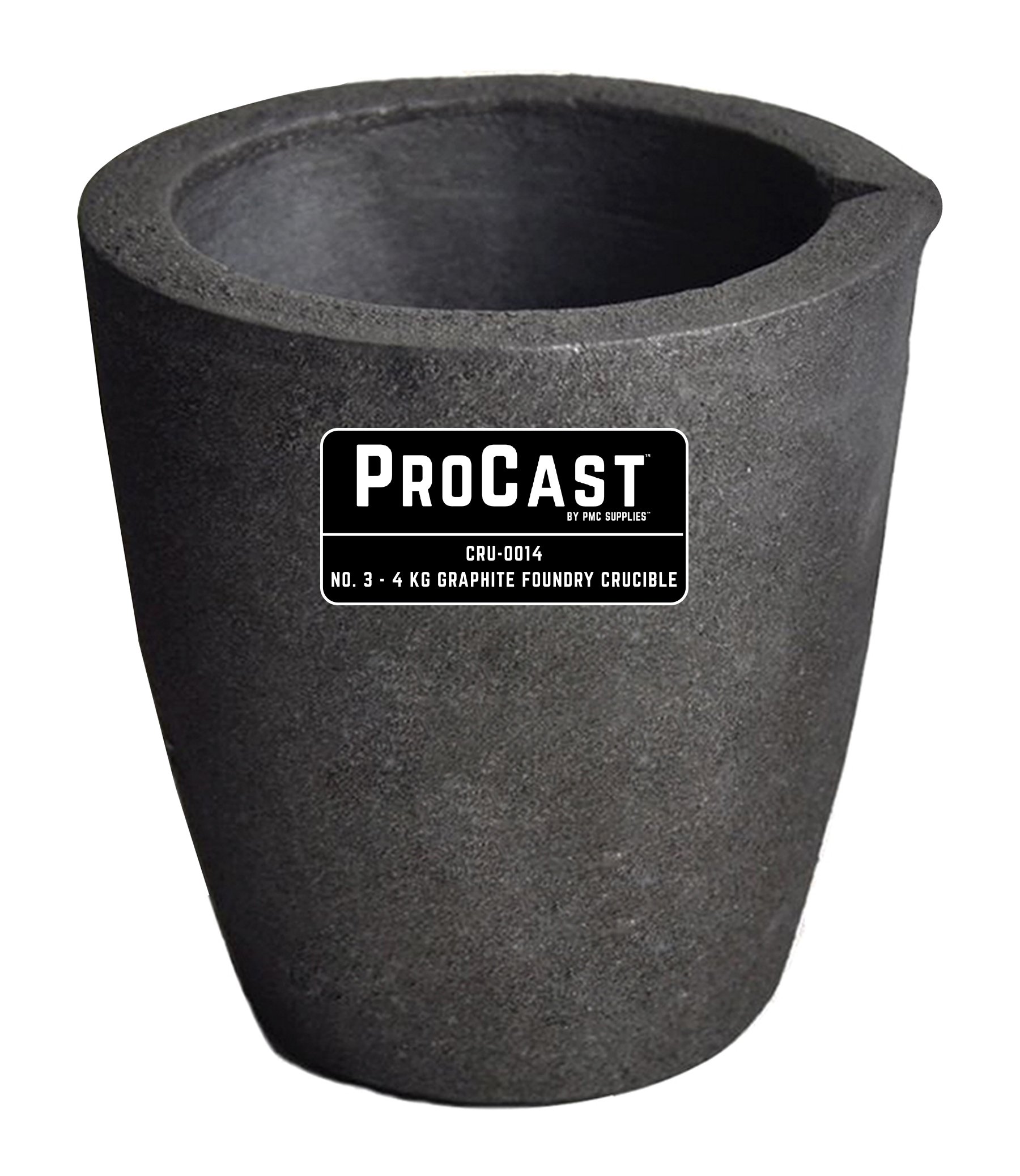

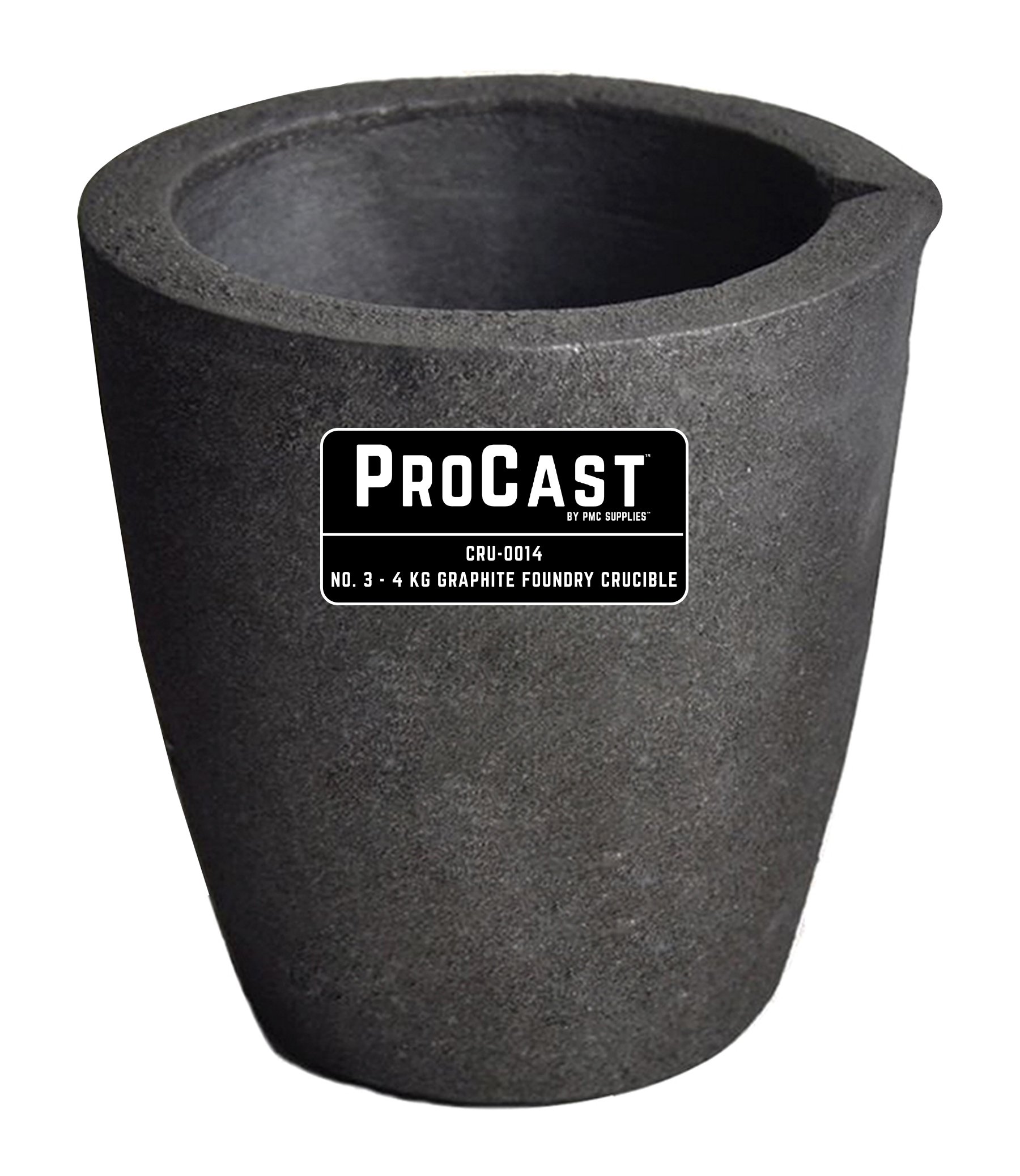

The #3-6 Kg ProCast Foundry Clay Graphite Crucible Cup is engineered for serious metalworkers, capable of melting a variety of metals including gold, silver, and aluminum. With a temperature tolerance of up to 2912°F and a capacity of 3-6 kg, this crucible is designed for use with propane torches and induction furnaces, ensuring precision and efficiency in your casting projects.

B**.

Several bronze castings later and still looking great.

This is the second of these crucibles (#3-4kg size) I have purchased, I'm very happy with both of them. The first was purchased about two years ago and is still in fine shape; the outside has vitrified significantly but the interior is still clean. As for the second one it has vitrified on the outside much more than the first but has retained its integrity. Some porosity is visible on the exterior but no damage is on the inside. As with the first one, the inside has stayed fairly clean and smooth. Casting brass definitely dirties the insides of these but they're pretty easy to clean up with a wire brush.To facilitate pouring (and also since the one I bought didn't really have one) I recommend using a round file to enlarge the pouring "spout" and also to round the inside edges of both the spout and the rim, this will help prevent fractures from expansion and contraction.Both crucibles I purchased have been used for casting brass, copper, and bronze, so were subject to heats of about 2000F. I also did some bronze smelting in these and they have held up wonderfully. This past summer I put the crucible through a rather intense few days of several melts of bronze for a University research project, including some pure copper melting at around 2000 degrees F. The crucible was heated an antique plumbers furnace, powered by propane. About 6-7 melts were done in one day with no averse effects on the crucible.Some things I have done which I think help to extend the lifespan:-Slowly heat the crucible up to your intended casting temp. and allow to cool fully before using it the first time-preheat the crucible for a few minutes to evaporate any moisture that could have build up since last use-Don't allow metal to harden inside the crucible-grip with tongs that are fitted specifically to the crucible to both ensure a good grip and prevent it from gripping too tightly-Don't store crucible outside or in a wet environment-refrain from striking crucible to shake out loose debris or cooled metalIn all I would absolutely recommend these crucibles as I have had excellent luck thus far.

J**N

Great Crucibles!

Thes crucibles work great!

M**E

Excellent graphite crucible!

Handles high heat well and is durable for multiple melts. The pour spout is a great addition. Be sure to preheat it properly to avoid cracking. Overall, a solid product for metal casting projects!

J**E

Truly amazing when all you have ever used is steel ones

This crucible is exactly what I was looking for. If you properly season it and HEAT IT SLOWLY!!! These types of crucibles WILL CRACK if you just throw them in a pile of already hot charcoal or coal or propane furnace!!! I placed it in my cold furnace, took a tiny torch to it at first, bright the temp up to 150 for 30 minutes and switched to a bigger torch and slowly brought it to 300F over the next 45 minutes to an hour, then stuck the heat to it. I was able to melt a full pot of brass, take it out, skim the dross, degas, and pour without even having to drop it back down in the furnace!! Truly amazing when all you have ever used is steel ones. Those things are cooling the metal to a solid in seconds. Made my own custom lifting and pouring tongs to ensure it fit perfectly. THE MOST IMPORTANT PART OF METAL MELTING!! Be safe people. These burns can and will cause permanent damage to the skin. Not to mention the fumes can kill or seriously injure you. All and all this is seriously a great product and I am purchasing another one as we speak. Great job PMC Supplies!!! You have provided professional grade foundry products at the fraction of the cost in my book!! You have a lifetime customer here!

B**N

Great customer support

My first crucible broke but they replaced it quickly

T**Y

Great crucible for Grant Thompson's foundry if you have propane

Hello everybody. Today I am giving my review o the PMC #3 crucible. I am going to target this review to a specific set of people who may find this useful, those with Grant Thompson's mini metal foundry. First of all I have had the foundry for going on 2 years and it is a champion. As first I began with charcoal but I recently upgraded to propane which I would suggest very much. A big point I want to bring up is that if you are using charcoal in TKOR's foundry this will most likely not work. My hole is a bit bigger than the video and it is a bit snug with propane. But if you have propane I would highly recomend going for the buy. If you have it I need to warn you of one thing, cracking. If you simply fire up the foundry and throw it in there it may crack. So the proper method to temper it is to put it in the oven for an hour to maybe 2 hours max. After this put it in the foundry and get it red hot then let it cool naturally in the foundry. After this it is ready for some fire. This crucible can take temperatures that go well above anything a charcoal or propane foundry can make. So have fun and be careful.Also some tips for the foundry with sand and plaster. Use steel wool or stainless steel pads in the wet mixture to make it last longer as suggested by Grant. Also if you want to make the propane furnace, go to my profile and look at the Propane Torch List for parts I use that are a fraction of the cost in Grants method. Thanks and have fun!

B**.

Takes the heat

I got this to melt copper and to replace a cheap one that actually melted. I guess you get what you pay for. Just temper first and you should have no issues with it. I've had my furnace up to 2300F and it handled it. Only complaint is mine didn't have the pour notch that's pictured, but a file will take care of that.Definitely recommend as I'll be getting more of these.

M**O

Crucible

Dent back came with no pooring spout like it shows in the photo

Trustpilot

2 months ago

2 weeks ago