Deliver to Paraguay

IFor best experience Get the App

🔧 Clamp in Style, Work with Confidence!

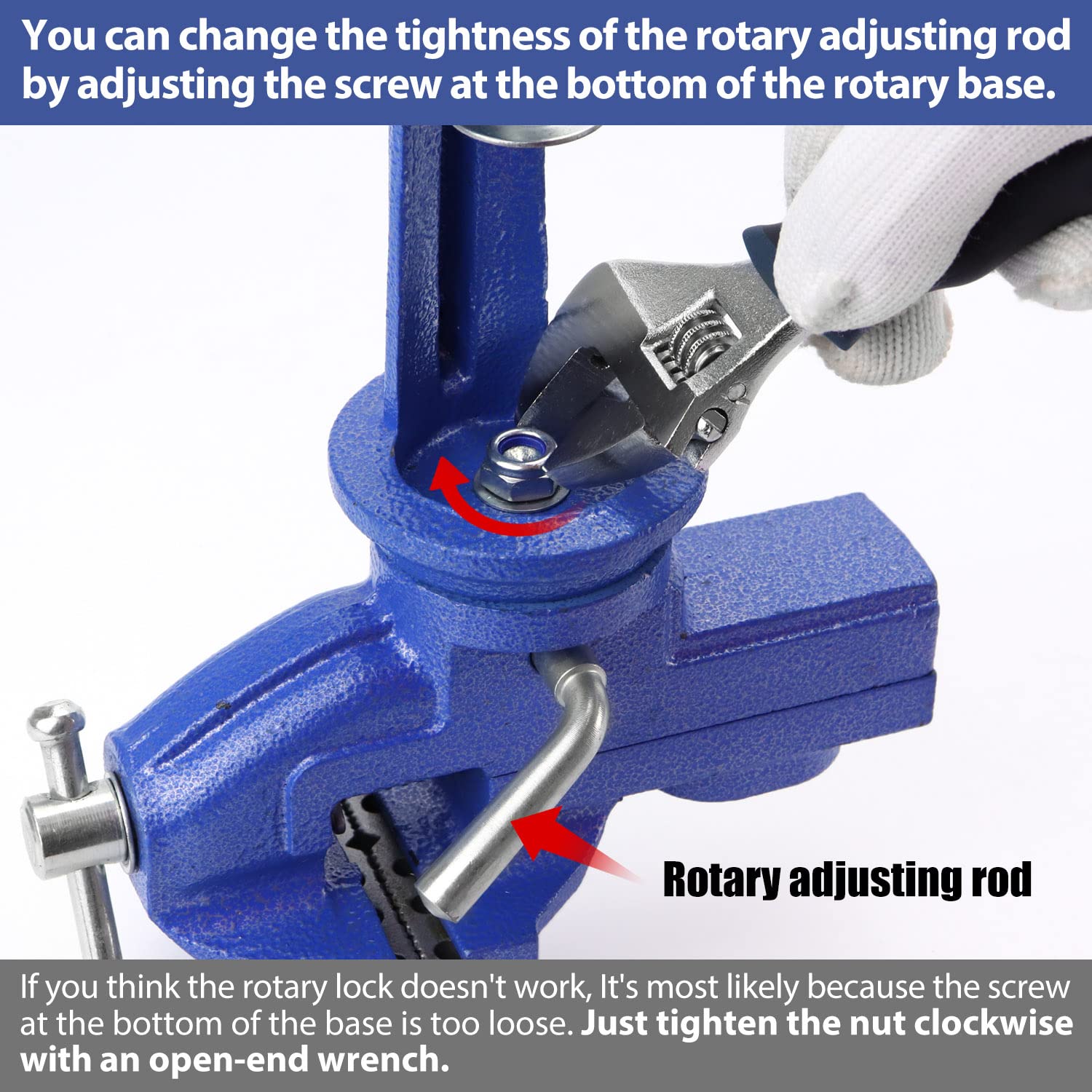

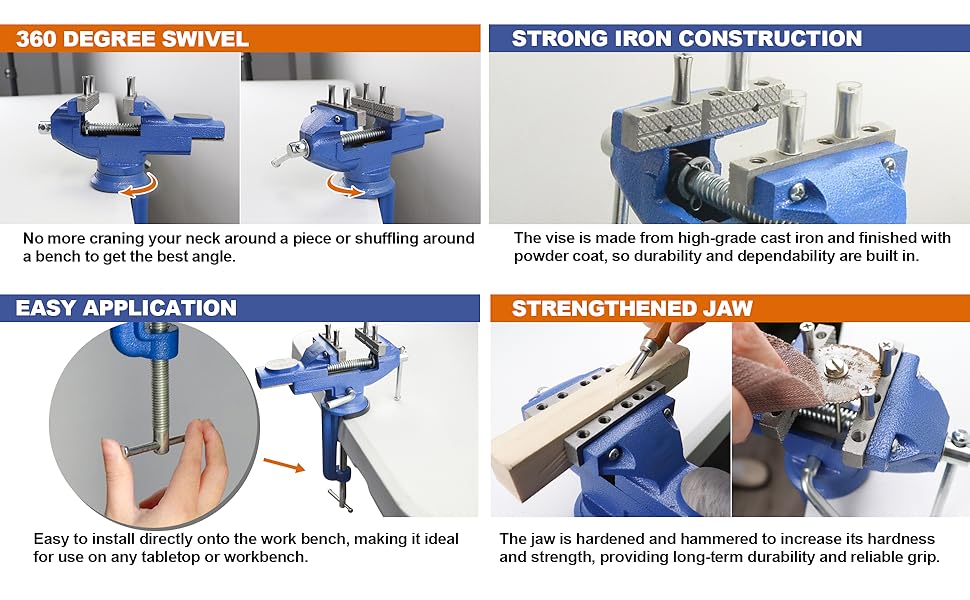

The POLIWELL 3-inch Bench Vise features a hardened steel jaw with anti-slip pattern, a 360° swivel base for versatile clamping angles, and an adjustable clamping system with 10 screw holes and 4 columns to hold irregular objects securely. Designed for woodworking, drilling, and precision tasks, it fits benches up to 4 inches thick and offers durable, corrosion-resistant construction for long-lasting use.

| Material | Alloy Steel |

| Brand | POLIWELL |

| Item dimensions L x W x H | 6.3 x 3.5 x 9.5 inches |

| Color | Vise-a |

| Style | Manual |

| Item Weight | 4.4 Pounds |

| UPC | 086291790738 |

| Manufacturer | Ningguo small monkey trade co. LTD |

| Part Number | BVBC3INM |

| Item Weight | 4.4 pounds |

| Product Dimensions | 6.3 x 3.5 x 9.5 inches |

| Item model number | BVBC3INM |

| Size | 3INCH |

| Item Package Quantity | 1 |

| Usage | Inside |

| Batteries Included? | No |

| Batteries Required? | No |

D**7

Great little vise - not heavy duty!

This is a great little vise if you need a light duty vise from time to time. It can be quickly attached and removed from a work bench as thick as 3.5 inches or so. I use it for holding turning blanks while I mark centers, holding scraper blades for sharpening and small tools for repairs.The jaws can be easily aligned using the two phillips-head screws that hold each jaw in the vise. Loosen the screws, close the vise with the jaws aligned, and tighten the screws again. The jaw faces have aggressive tooling - you'll want a set of jaw caps to use for almost anything. I've had good luck with FRICTIONWORKS Premium 4" Vise Soft Jaws. Anything you buy will be oversized, but these have strong magnets to hold them on the vise.The "clamping posts" are useful. I've used them to bend wire for hooks as well as for holding odd shaped items. The swivel ability is also good.One thing to note: they put what looks like a flat "anvil" area behind the rear jaw. Don't be tempted to use it! The back of the rear jaw is hollow and the top of the casting is barely 3mm thick. If you have the vise open at all there'll be no support under the rear jaw. I'm pretty sure any strike would shatter the casting.Like the title says, this isn't a heavy duty tool, but it can meet a lot of needs in your shop.

D**Y

Amazing little vice

The description of this device does not do it justice. While the workmanship is not the greatest its best features are not mentioned. Yes, it does come with four "clamp posts" but these posts are supplied covered with a tough silicone rubber sleeve. This sleeve makes the clamping of round or other shaped plastic parts VERY easy, and there are not a lot of products on the market that do this job as well. The clamp posts have a Phillips socket on their end, so they are inserted and tighten easily. The plastic pads for the bench vice could be better engineered, but they work.

J**S

Serviceable, reasonable price

Not what I'd call a quality tool, but I feel like I got what I paid for. The jaws are very poorly made and fit rather haphazardly, but are functional.

F**C

A handy tool for the hobby user

The quality of Chinese tools is much better than years ago. The overall design is very good. The way the jaws are oriented is much better than other small vises. The jaw faces are nothing special to look at but do the job. The jaw faces are screwed on in such a way that attaching softer non-marring faces made of wood or other materials can be easily screwed on in place of those provided. So, yeah, it’s made in China but it works well for a small hobby vise and it is more than worth its price. The product’s advertising is an accurate description of what you’ll get.

H**1

Well, to be honest....its just "OK".

First: this is NOT a large vice. Its small and light weight.I have around ten or twelve vices of various sizes and types due to doing a lot of shop work of all different types. I have vices that have survived heavy use for over fifty years and will outlive me. This vice will not manage that type of service life and one should not expect that in this price range. I got this vice due to it having pins that screw in allowing it to hold oddly shaped parts. Its the only vice I own that has the pin set up which is why I added it to my tools.I like to be honest and give fair reviews and on this item I can not rave about it. It is light weight. It is a low end product that will function but it has a lot of quality compromises. Compared to other vices I have in this size and price range it does not stand out. In fact I have to say that while it is functional to a degree for very light work it is not up to the build quality of some lower priced vices I have bought from the local HF store. Things fit poorly and the metal doesn't appear very robust.The only stand out feature of this vice is the the ability to put the pins in the vice for holding odd shaped, curved parts. As has been pointed out by others the pins are a loose fit and not very durable for anything more than very light work. If you are only planning light usage and the pins are important than perhaps this vice will meet your needs. If you are planning on anything more than that then likely you should look elsewhere.Would I recommend this to a friend or buy another? Probably not if they expected a high grade tool. I did not sent it back as I am aware of its limitations and accept those.

N**N

Small but mighty

It's smaller than what your grandfather had in his garage but it's easy to use, easy to move and does the job. I like mine and would recommend it to anyone that’s looking for a small vise.

M**N

Excellent make

It is as advertised, well made and sturdy

B**D

Nice value for the money, but see note below

This is a light duty bench clamp that I use for modeling. There are several complaints by other reviewers concerning the main jaws not aligning properly, but this is easily overcome because the jaws are actually adjustable to the degree necessary for good alignment. Here's what you do: First, loosen the 4 philips head screws that hold the jaws in place, two on each jaw. Just loosen a few turns and do not remove them. Second, looking down on the center of the jaws, notice that there is a triangular alignment hole. Put a bolt slightly larger in diameter into this hole and tighten the clamp down on it. This will bring the jaws into proper alignment. Third, now firmly retighten the 4 philips head screws to maintain proper alignment. Back off a bit on the jaws and remove the alignment bolt. You're done.

Trustpilot

2 days ago

2 weeks ago