Sobre nosotros

Servicios al cliente

Atención al cliente

Acceso Regional

Legales y políticas

Obtén la aplicación

Apunta tu cámara para descargar la aplicación

Copyright © 2024 Desertcart Holdings Limited

✨ Elevate your 3D prints to showroom shine 🧴

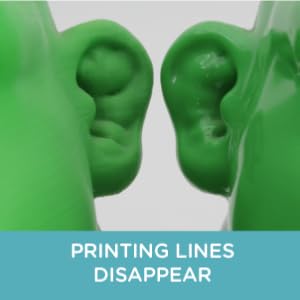

Polymaker PolySmooth PVB filament is a 1.75mm, 0.75kg beige filament designed for easy, smoothable 3D printing. It prints like PLA but can be post-processed with isopropyl alcohol (IPA) to achieve a glossy, layer-line-free finish. The filament is vacuum-sealed with desiccant to prevent moisture absorption and is engineered to avoid warping, jamming, and delamination. Ideal for professionals seeking flawless prints and seamless finishing, especially when paired with Polymaker’s Polysher.

| Manufacturer | Polymaker |

| Brand | POLYMAKER |

| Item Weight | 1.65 pounds |

| Product Dimensions | 6.3 x 7.87 x 2.36 inches |

| Item model number | PJ01012 |

| Color | 102 - 1.75mm Beige (Hex Code: #Ebd591) |

| Material Type | Polyvinyl Butyral |

| Number of Items | 1 |

| Size | 0.75kg |

| Ink Color | Beige |

| Manufacturer Part Number | PJ01012 |

J**H

Coolest filament I've used in a long time!

There was a bit of an odd smell while printing, just enough to open a window. Otherwise, this stuff prints like PLA. After it was done printing, I used a fine mist of rubbing alcohol and in 20 minutes my print had a mirror finish using the black filament.

G**S

My Polymaker Polysher works exactly as described. No problems encountered.

So far, it is working exactly as advertised. Purchased this in addition to a CEL Robox Dual 3D printer. The Polymaker Polysher is a nice looking and well constructed piece of kit, but does lack the solid feel suggestive of its sleek appearance. When working with $1,500-$4,200 3D printers in the lab, this machine suddenly feels like handling a consumer grade coffee maker. That being said, it is still more than what one would expect for the relatively low cost in my opinion and shouldn't affect longevity in any way.The nebulizer works perfectly with my machine. The reports of the unit shutting down after a few seconds is probably from lack of priming. Be sure to saturate the foam wick vs "a few drops" as in the instructions. The machine shuts off if the piezo nebulizer element is not wet, the self priming feature will not work if any dry pockets exist in the foam wick as it relies on capillary action.The "eject" mechanism is indeed very slow, almost annoyingly so but for a reason. It lifts slow to prevent uplifting of the vapor remaining in the chamber. Overall, I am very pleased with this device. It would be nice if the lift mechanism was a little quieter (sounds like a gearbox from a toy), but the turntable motor is absolutely quiet. I will update my review as I gain more experience in the months ahead if problems. The unit is well sealed with a silicone gasket and there is no odor of alcohol vapor during operation. Quite pleased overall.

C**Y

So brittle it’s unprintable

I tried using this for support material for PLA on my prusa XL5t. I had tried a roll of tronxy pva, which started very brittle and stayed that way despite days of drying and careful storage.For the first 3 prints this PVB worked great. After that i can only get about 1/2” height into a print before the filament breaks in the extruder and stops feeding. I tried reducing the pressure on the filament to the point i could pull it backwards, with no change.This roll has either been under vacuum with 50g of new silica gel, or in my sunlu s4 at 50C since i opened the factory packaging. Hygrometer in the vacuum bag has remained at 15% the entire time.This is the first time polymaker has let me down.

R**K

UPDATE! Amazing Product and Customer service!

The media could not be loaded. Firstly, the Polymaker Polisher and Polysmooth filament are game changing products. If you are looking to produce professional looking parts with a smooth glossy finish than this is a must have.Additionally, the Polysmooth filament prints better than any filament that I have ever used. Briefly, I own four 3D printers and print daily. Ease of use and breathtaking results make the Polymaker polisher a worthwhile investment for anyone serious about 3D Printing.Lastly, the customer service provide by Polymaker is outstanding! In fact, with the exception of Amazon I have never experience customer service like Polymaker’s. For example, I recently had to return a defective unit as the platform would not raise or lower after about 2 weeks of extensive use.After informing Polymaker of the issue they generously offered to send me a brand-new machine. However, I had already initiated the return process with Amazon so that I could purchase another Polysher. As a result, Polymaker could not send me a new machine as I had already begun the process of purchasing another one.Instead, Polymaker sent me a brand-new roll of Polysmooth filament free of charge! Even better it was the color that I have always wanted to try. Their customer service is fast and responsive. I will be purchasing all of my filament exclusively from PolyMaker.So far the new Polisher has been fantastic! I will continue to post updates.

P**E

Very impressive device for post-processing 3D prints...now with an update.

Being very intrigued with the idea that my 3D prints could be "polished", I took a chance on the Polymaker Polysher despite the low ratings it has received so far on Amazon. The Polymer Polysher arrived very well packaged, first in a outer shipping box that held Polymaker's own shipping box, inside of which is the actual PolyMaker packaging. The instructions for setting up the Polysher the first time are very informative and the only small issue was a loose heat seal along the clear plastic hood which was easily reseated.Of course, this device only works with the PolySmooth filament but the results are very impressive. The Polysher creates a very smooth and shiny result, remaining shiny after the alcohol evaporates away. You'll get better results with prints done at higher resolutions. Even low-resolution prints come out quite nice but nowhere near as nice as those done at a high resolution setting.The PolySmooth filament (sold separately but required for the Polysher to work) is not PLA and requires slightly higher temperatures than the PLA preset in my version of CURA. It was easy to setup a new profile with the necessary adjustments and the filament is working nicely creating nice prints even without the use of the Polysher. While not necessary, I would think that a heated bed would be useful to increase adhesion.My first print encountered the same problem mentioned in other reviews. The unit shut down with an error after 5 minutes of polishing. Resetting the timer and restarting the polishing process solves the problem. My second print worked straight through with no problems.I've only had the Polysher for a few days but so far I'm very impressed with the results I'm getting. If you're okay with working within the closed eco-system of Polymaker's products, the results are very good and I'm actually very enthusiastic about continuing to use this to post process my prints. I'll update my review if I encounter any problems over the next few weeks.Update: August 2017So I've had the Polymaker Polysher for a few months now and it continues to do what it advertises and in general I've been very happy with the results. The only problems I'm encountering are the continued nebulizer halts about 5 minutes into the procedure. Sometimes it only happens once, sometimes it happens a couple of times in a row. This has the unfortunate side effect of prolonging the smoothing process and requires a bit more supervision. I find myself starting the process and waiting around for the first 5 minutes for the unit to shut off, another few minutes for the unit to evacuate the mist and then resetting the process. It usually works the second time through but there have been times I've had to restart the process more than once.Also, I'm having problems with the Polysmooth filament. Perhaps it's very susceptible to changes in the atmosphere (it is summer with its inherent increases in heat and humidity) but I'm finding it very difficult to get clean prints anymore. I do store the unused filament in the included resealable bag with a package of desicant but most prints these days don't have the look of a recently opened spool of filament. I'm getting lots of stringing or bad layer adhesion resulting in gaps. I'll have to reach out to Polymaker to see what could be done to improve my printing.Nonetheless, it's still an interesting product and I generally have had a lot of success with it. I hope that efforts are underway to improve the product and fix the various problems that have been reported.

J**L

Price and quality

Lead time and price,

Trustpilot

Hace 2 meses

Hace 1 semana